ISO 22000:2018

ISO 22000:2018 is an international standard that focuses on the hygiene and safety of the food products and related processes. The guidelines cover the entire supply chain management for organizations involved with food and related products. This includes companies dealing with raw materials, production, storage, packaging and delivery of food products. The standard aligns with the local regulations for food safety and other related quality management systems.

The requirement for a food safety management system (FSMS) comes in to maintain the health and safety of not only the consumers but also for the people involved in the different processes. The organization must plan, implement, operate, maintain and update an FSMS as well as to conduct regular evaluations of the processes. This allows the company to provide products and services that are safe, per their intended use.

This international standard states largely generic requirements for companies in the food and related industries. The requirements define what an enterprise must do, so that it can demonstrate its ability to control food safety hazards and ensure that food is safe for consumption. As other ISO management system standards, 22000:2018 also is designed with a structured framework, but can be incorporated efficiently within the organization’s existing operations and existing management systems.

With rising ill-effects on human and animal life because of poor food quality and safety management, having a strong system ensures many benefits for the company. The company will minimize incidents of food borne diseases and related concerns. The certification is sure to raise confidence and trust in the enterprise’s operations and products.

The standard dictates that the company streamline its processes, in turn ensuring effective management and use of resources. There must be proper planning, documentation, implementation and review of the standards that were adopted. This also leads to regular evaluation and upgrade of systems, so that the organizations maintain or improves its safety standards.

ISO 22000:2018 was released on 19 June 2018, and is an international standard. As it follows the same High-Level Structure (HLS) structure as other widely applied ISO standards, such as ISO 9001 and ISO 14001, it will be easier to integrate with other management systems.

If you are already applying ISO 22000:2005, you will recognize most of the requirements in ISO 22000:2018. However, there are quite a few changes from ISO 22000:2005 that you must prepare for in order to transition and comply with ISO 22000:2018.

These are some of the key changes to consider:

- Changes due to the adoption of HLS

- Business Context and interested parties: Chapter 4.1, external and internal issues, introduces new clauses for systematic determination and monitoring of the business context, and Chapter 4.2, needs and expectations of interested parties, introduces demands to identify and understand factors that can (potentially) affect the ability of Management System to reach the intended results.

- Strengthened emphasis on leadership and management commitment: Chapter 5.1 now includes new demands to actively engage and take accountability for the effectiveness of the management system.

- Risk management: Chapter 6.1 now requires companies to determine, consider and, where necessary, take action to address any risks that may impact (either positively or negatively) the ability of the management system to deliver its intended results. Strengthened focus on objectives as drivers for improvements: these changes can be found in Chapter 6.2, and performance evaluation chapter 9.1.

- Extended requirements related to communications: Chapter 7.4 is now more prescriptive in respect to the “mechanics” of communication, including determination of what, when and how to communicate.

- Less strict requirements for a food safety manual: – the change is introduced in chapter 7.5. It is still required to have documented information. Documented information shall be controlled to ensure it is adequately protected (ref. 7.5.3). The explicit requirement to have a documented procedure has been removed.

- Other changes that are specific to ISO 22000 and food safety management

- The PDCA cycle: the standard clarifies the Plan-Do-Check-Act cycle, by having two separate cycles in the standard working together: one covering the management system and the other, covering the principles of HACCP.

- The scope now specifically includes animal food: food for animals not producing food for human consumption. Feed is intended to be fed to food producing animals.

- Some important changes in the definitions: ‘Harm’ is replaced by ‘adverse health effect’ to ensure consistency with definition of food safety hazard. The use of ‘assurance’ highlights the relationship between the consumer and the food product, based on the assurance of food safety.

- Communicating the food safety policy – Chapter 5.2.2: Explicitly requires the management to facilitate understanding of the food safety policies by employees.

- Food Safety Management System Objectives: Establishing objectives for the food safety management system is further specified in Chapter 6.2.1 and includes items as e.g. ‘consistent with customer requirements’, ‘monitored’ and ‘verified’.

- Control of externally-provided processes, products or services – Chapter 7.1.6: This clause introduces the need to control the suppliers of products, processes and services (including outsourced processes) and to ensure adequate communication of relevant requirements, to meet the food safety management system requirements.

Involvement of the management team

Food safety is not just something to be handled by the quality department. It is a top-management issue. ISO 22000 focuses on the involvement of the management team, which has to develop overall policy.

Communication

As food safety hazards may be introduced at any stage of the food chain, interactive communication both upstream and downstream is essential. In addition, internal communication is a key element to avoiding misunderstandings and minimizing risks. A common vocabulary is a great help in this connection.

The HACCP (Hazard Analysis & Critical Control Point) principles

ISO 22000 combines the recognized HACCP principles with prerequisite programmes. The hazard analysis determines a strategy and the prerequisite programmes set up an action plan.

System management

ISO 22000 relies on a structured management system based on relevant parts of ISO 9001. It is possible to integrate them into one management system together with ISO 14001.

Prerequisite Program

The prerequisite programmes are classified into 2 subcategories. The Infrastructure and Maintenance programs which cover permanent features in food safety. The Operational prerequisite programs are designed to reduce the risk of hazards in the product or processing environment.

Examples of FSMS Objectives:

Target line: Yearly

To respond to customer complaints within x hours

To reduce the number of customer complaints by x% on previous year.

To maintain a minimum 'G-rating' for our third party certification audit.

To complete all verification activities within 5 days of the scheduled date.

To complete food safety induction training for new employees before job commencement.

To ensure that there is no listeria monocytogenes detected in any of x product.

To maintain a minimum of x% for all internal GMP audits.

To not have any food recalls during the present year.

Related Services

FSSC 22000 v5.1

FSSC 22000 v5.1

BRCGS for Storage & Distribution Issue 8

BRCGS for Storage & Distribution Issue 8

BRCGS for Storage & Distribution Issue 6

BRCGS for Storage & Distribution Issue 6

ISO 22716:2007

ISO 22716:2007

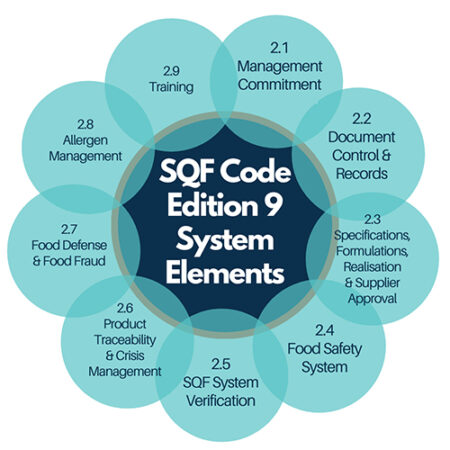

SQF Code Edition 9

SQF Code Edition 9

BRCGS for Storage & Distribution Issue 4

BRCGS for Storage & Distribution Issue 4

IFS Version 7

IFS Version 7

FAMI-QS

FAMI-QS

HALAL

HALAL

KOSHER Certification

KOSHER Certification